Pre-Certified Modules Help, But Whole Product Testing is Still Required

Integrating wireless technologies into a new product means navigating the Federal Communications Commission (FCC) certification process. While some developers choose to incorporate pre-certified RF modules—such as those for Wi-Fi or Bluetooth—to streamline certain aspects of compliance, it’s crucial to understand that using a pre-certified module does not fully exempt your product from FCC testing and approval. Ultimately, your finished device as a whole must still meet FCC requirements before it can be legally marketed in the United States.

What Are Pre-Certified Modules?

Pre-certified modules are RF components already tested against FCC standards. By integrating such a module, you may avoid some initial RF tests, potentially reducing time and complexity. However, the presence of a pre-certified module doesn’t guarantee that the final, assembled product is FCC-compliant.

Why Still Test the Entire Device?

When you integrate a pre-certified module, factors like your product’s enclosure design, antenna configuration, or the presence of additional RF components can alter the overall emission characteristics. This means the entire product must undergo evaluation to confirm it meets FCC standards. The module’s prior approval helps, but doesn’t replace verifying the final device’s compliance.

Benefits of Starting With Pre-Certified Modules

| Traditional Certification | Using Pre-Certified Modules | |

|---|---|---|

| Time to Market | Longer, due to extensive testing | Shorter, with reduced compliance testing |

| Certification Costs | Higher, due to multiple testing phases | Lower, with pre-certified components |

| Compliance Complexity | High, requires detailed compliance work | Low, simplified by pre-certified modules |

| Testing Requirements | Extensive testing for each component | Limited testing focused on integration |

| Risk of Delays | Higher, due to potential testing issues | Lower, with pre-certified components |

Even though using a pre-certified module can simplify parts of the process, the entire product must still be tested to ensure final compliance. The table above illustrates key differences, but both paths ultimately lead to verifying your fully assembled device.

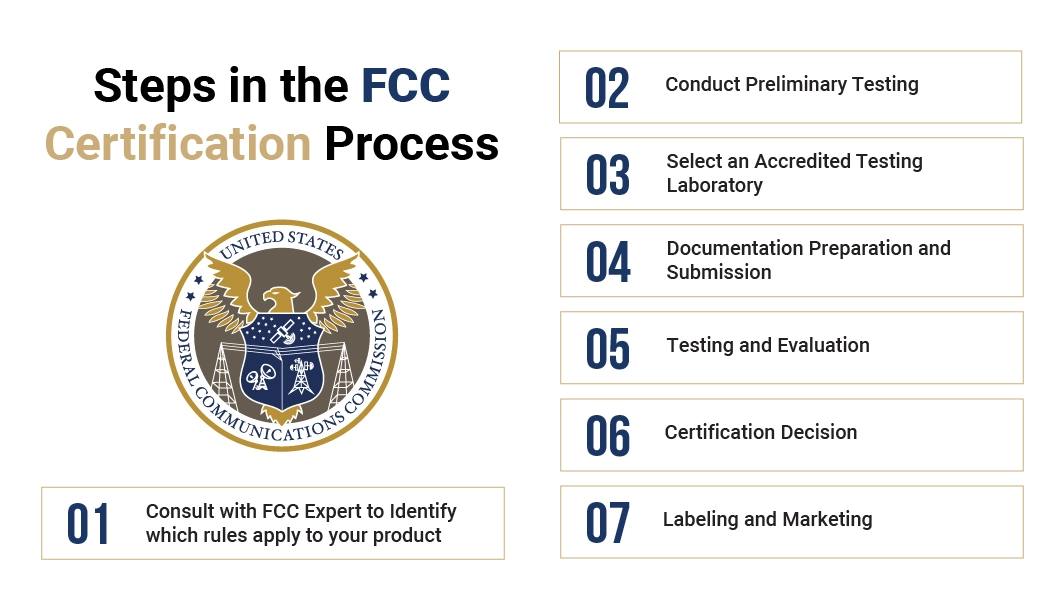

Steps in the FCC Certification Process

Step 1: Identify Applicable FCC Rules

Determine the specific FCC rules (often Part 15) that apply based on frequency, power, and intended use.

Step 2: Conduct Preliminary Testing

Before formal tests, consider pre-compliance checks to catch emission issues early—especially since changes in product design can impact how a pre-certified module behaves.

Step 3: Select an Accredited Testing Laboratory

Choose a reputable lab familiar with FCC testing protocols. They will guide you on necessary tests and help confirm that your device meets all requirements.

Step 4: Prepare Documentation and Submission Materials

Compile detailed schematics, photographs, user manuals, and other documentation. This ensures the lab and Telecommunication Certification Body (TCB) fully understand your product’s final configuration.

Step 5: Testing and Evaluation

Products must undergo testing in accredited laboratories to measure their electromagnetic emissions and ensure compliance with FCC regulations. The testing evaluates whether the product meets the required limits for EMI/RFI emissions. The required testing typically includes:

Emission Testing:

Radiated Emissions: Measures the electromagnetic energy emitted by the product into the air, conducted in an anechoic chamber to ensure emissions are within FCC rules.

Conducted Emissions: Assesses electromagnetic interference emitted through power cords using a line impedance stabilization network (LISN).

Immunity Testing (for certain products):

Electrostatic Discharge (ESD) Immunity: Tests the product’s resistance to static electricity discharges.

Radiated Immunity: Ensures the product operates correctly when exposed to electromagnetic fields.

Spurious Emissions:

Measures emissions at frequencies outside the primary operating range to ensure they are below allowable limits.

Harmonic Emissions:

Assesses emissions at harmonics of the fundamental frequency to ensure compliance with FCC limits.

AC Power Line Conducted Emissions:

Measures the emissions conducted along the AC power lines to ensure they fall within the acceptable limits.

Unintentional Radiators (Part 15 Subpart B):

Tests ensure that devices not intended to emit RF signals do not exceed emissions limits specified by the FCC.

Intentional Radiators (Part 15 Subpart C):

For devices designed to emit radio frequency signals, testing ensures compliance with the specific limits and conditions of FCC rules.

If results show any non-compliance, modifications may be required, followed by re-testing until the device meets FCC standards.

Step 6: Certification Decision

The TCB reviews the lab’s test reports and your documentation. Once it confirms full compliance, your product gains FCC certification.

Step 7: Labeling and Marketing

After successful testing, the product must be labeled with an FCC ID number to ensure all required user notices and guidelines are included. With certification in hand, your product is ready for the U.S. market.

Conclusion: Ensuring Full Compliance With Product-Level Certification

A pre-certified module is a helpful starting point for FCC compliance, but it doesn’t replace the need to test your entire device. Ultimately, product-level certification is about confirming that every component, including the pre-certified module, works together without exceeding FCC emission limits or other requirements. By recognizing this from the start, you can plan accordingly—ensuring that your product as a whole achieves the compliance needed for a successful market launch.

Kickstart Your Projects With CEL Wireless Modules today!

CEL’s has a range of Pre-Certified wireless modules